China Thermal Fuse Manufacturers

- PRODUCT DETAIL

Thermal fuse manufacturing

Thermal fuse manufacturingThe thermal fuse is a non-resettable, one-time overheat protection element, and the current fuse is a one-time overcurrent protection element. Series connection in a variety of electrical power input, when the use of household appliances in the abnormal temperature changes, or temperature out of control lead to excessive temperature rise, the thermal fuse can quickly cut off the circuit to avoid the occurrence of fire.

Commonly used in: hair dryer, iron, rice cookers, electric stoves, transformers, motors, drinking fountains, coffee pots and so on.

We not only related to the product structure and technology, more in-depth to the core of the product - Fuse materials development and application, such as fusible alloy wire, lead antimony alloy wire, organic mixture and so on. To provide you with one-stop from the rapid proofing to small batch production services. Please contact our professional team, let us come for you to achieve all the technical requirements.

What Is Thermal Fuse?

Thermal fuse, is overheat protection components, also known as temperature fuse or Thermal Cutoff (GB GB1616.1-2013), widely used in electrical overheating protection.

The temperature sensing portion can be divided into:Fusible alloy wire and organic particle type temperature fuse, after fusing once cut off the current, non-recovery type thermal fuse.

Features Of Thermal Fuses

In Yaxun can provide a full range of thermal fuses, from your first consultation message to the final product delivery, you can get our engineers and sales staff professional, personalized service.

(1) high precision operating temperature, fusing action is reliable, not premature or delayed blown;

(2) good thermal stability, long-term in a high temperature state will not get out of control;

(3) load current up to 20A, it can be adapted to use a large current household appliances;

(4) the shell is not charged, the use of safe, easy to install;

(5) low prices, to adapt to mass production.

(6) temperature response speed;

(7) small size, easy to install.

(8) Structural accurate, resistance to vibration, impact resistance, applicable to household appliances, industrial circuit overheating protection;

Structural Classification Of Thermal Fuse

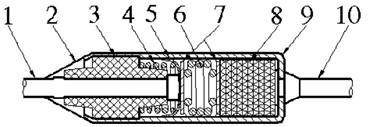

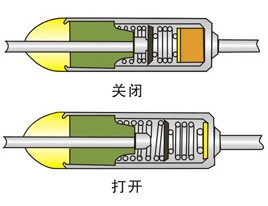

organic type metal shell temperature fuse is a combination, the composition of the structure are:

1. Pin (A), 2. Sealed resin, 3. Insulating ceramic, 4. Fine spring, 5. Star reed, 6. Coarse spring, 7. wafer, 8. temperature sensing block, 9. The housing, 10 Pin (B).

When the temperature insurance is in normal operation, the current flows from the left lead to the sliding contact and flows through the metal housing to the right lead. When the external temperature reaches the predetermined temperature, organic matter can melt melt, the compression spring will become loose. That is, spring expansion, sliding contact (slidingcontact) and the left side of the separation. The circuit will cut off, the current between the sliding contact and the left lead is cut off. the temperature fuse will fail and can not be used again.

2, easy to melt alloy wire thermal fuse has ceramic shell and square shell, its temperature sensing element is a fusible gold.

Product structure: is the axis of the symmetrical lead, fusible alloy wire, and resin mixture and insulated porcelain tube, plastic shell.

When the temperature rise of the heating element is set to a temperature, the resin mixture begins to liquefy, when the melting point is reached, with the help of the resin mixture (increasing the surface tension of the melted alloy), has been molten alloy wire in the resin mixture under the action of tension, quickly to both ends of the wire as the center shrink into a spherical, and thus permanently cut off the circuit.

Technical Parameters And terminology Of Thermal Fuses

(1) Rated operating temperature (Tf):

The temperature fuse is tested according to the standard method to change the temperature of its conductive state. According to IEC6091 standards-based security provisions, the temperature fuse must be operated within the rated operating temperature + 0 / -10 ° C (the Japan Electrical Supplies Act provides a tolerance range of ± 7 ° C).

(2) Operating temperature Found:

The temperature fuse is heated in the silicone oil tank at a rate of 0.5-1 ° C per minute, detection current is less than the fusing temperature measured at 10mA condition. It is the actual operating temperature of the temperature fuse.

(3) Holding temperature (Th):

When the temperature fuse passes the rated current, can hold for 168 hours without changing the maximum temperature of its conductive state.

(4) limit temperature (Tm):

Temperature fuse can withstand the maximum temperature for 10 minutes reconnection phenomenon never occurs.

(5) Rated current (Ir):

The maximum current that the temperature fuse can carry.

(6) Rated voltage (Ur):

Temperature fuse maximum operating voltage.

Precautions For Use Of Thermal Fuses

The thermal fuse is a sensitive protective element, in the use of the process, need to pay attention to some specific parameters, the use of the correct installation method in order to properly use the product, Can reduce the risk of improper operation of the temperature fuse caused by incorrect design and installation methods.

Design And Selection Criteria:

1, each temperature fuse has its rated electrical characteristics and temperature parameters, the product must be used within the specified rated parameters.

These parameters include Tf (rated operating temperature), Th or Tc (hold temperature), Tm (limit temperature) and rated current, voltage, see "Temperature fuse specification table" for details.

2, the installation design should pay attention to the temperature fuse of the long-term continuous working environment temperature should not exceed their holding temperature.

3, the temperature of the temperature of the fuse body due to power and cause their own fever and higher than the ambient temperature. Depending on the installation method and status, the rising temperature may be higher, it is recommended to use a thermocouple to test the temperature of the heating element at the time of design, and then determine the rated temperature of the temperature fuse and the mounting position.

4, the temperature fuse is a non-resettable thermal protection device, for safety reasons, when replacing the temperature fuse, use the same type of temperature fuse and install it in the same position.

The Mounting Position Of The Thermal Fuse

● When designing the product installation position, let the temperature fuse close to the heating body, the temperature fuse should be installed in the machine prone to failure, abnormal heat the most sensitive position.

In order to increase the sensitivity of the temperature fuse to temperature, need to make the temperature fuse and heat a larger area of contact.

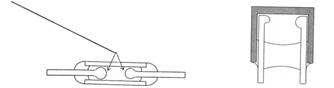

For example, the motor coil is fitted with a thermal fuse:

When used on motor windings, if possible, the temperature fuse should be buried in the coil winding, speed up the heat conduction, improve the sensitivity of the temperature fuse.

Installation Considerations OF Thermal Fuse

● In the installation of products, must be considered with the lead, shell contact casing material shrinkage, expansion tension, use a soft, bendable low-resistance lead to connect to the temperature fuse.

● Do not install the temperature fuse in a violent vibration.

E.g:

In the case of waste heat overshoot "may exceed the limit temperature. Hair dryer in the air inlet or outlet blocked, causing the temperature rise to Tf, then the temperature fuse disconnect the circuit, however, an incorrect design may cause the device to open the circuit ahead of time and excessive waste heat overshoot may damage the fuse, the application product shall be tested to determine the temperature fluctuation of the heater due to normal temperature fluctuations (such as the operation of the temperature controller and the reset), the ambient temperature of the temperature fuse does not reach Tm in the temperature cycler cycle.

●The contact resistance must be controlled to ensure that the resistance is minimized, improper connection will lead to early action of the fuse, the contacts must be inspected to ensure proper mechanical strength at the connection. inappropriate connection points will lead to increased contact resistance and then produce high temperature in the contacts, causing damage to the sealing resin and other components, which may cause the device to produce an abnormal open circuit or other failure.

● Crimp

Lead wire and a variety of shapes of crimp terminals directly crimp, crush parts can not be loose, to completely compact, because in order to avoid crimping loose, caused by contact resistance increases heat generation.

● Solder

If the temperature fuse to use solder or dip tin way with the line connection, solder or dip tin is best from the temperature protection body 10mm or more. in the case of 300 ℃ solder or dip tin time should be controlled in 1 to 2 seconds is appropriate, use a fuse below 113 ° C as far as possible without using solder or dip tin. to prevent premature rupture due to heat.

● Bend

When fixing the temperature fuse with screws or rivets, fixed point should be more than 10mm from the warm-keeping body, do not pull the lead when the screws or rivets are locked, to prevent the tension is too large, will lead strain, or from the hot melt fracture and affect the normal use of temperature protection. For details, please see the fuse pull standard.

Epoxy resin package end of the lead wire for bending use, please carry out 8mm away from the epoxy resin parts, so as not to damage the insulator, the other end of the lead wire bending, at a distance of 5 mm from the housing. when bending, bend the lead wire (the epoxy does not apply force) while bending it.

● not knob temperature fuse (e.g.: pin rotation relative to the housing).

● The pin can not be damaged during installation, hit the gap, sharp angle bending, burning.

● Sealing resin and shell can not be damaged, burning or overheating.

● purchase must be tested to see if the damage occurred in the transport process, it is recommended to do the test again after installation. it is advisable to conduct conductive measurements before and after installation (ie, within 2mΩ of product resistance measured at 10mm from the product body) or X-ray inspection.

● Avoid the use of water, organic solution and other liquid or condensation conditions, do not use sulfur dioxide, hydroxide and other corrosive gases in the environment.

PREVIOUS:NONE

NEXT:China Whirlpool Dryer thermal fuse price

NEXT:China Whirlpool Dryer thermal fuse price