Motor Protection Standard _ Overcurrent Protection, Overload Protection, Overheat Protection

Motors are often used in daily life and in all walks of life. If the motor is not protected, it may cause a safety accident. This article discusses the overheating protection of the motor for the danger of overheating.

The dangers that may occur in motor-driven appliances during use are the risk of electric shock, fire and overheating. There are many reasons for the motor to overheat, such as overloading, improper selection, cooling failure, lack of monitoring, and necessary maintenance leading to premature insulation aging. The motor generates losses during operation. These losses reduce the efficiency of the motor on the one hand, and the loss of heat into the motor on the other hand, causing the temperature of the motor winding to rise. The service life of the winding insulation material is related to its working temperature. If the temperature is too high, the insulation material will accelerate aging, which will drastically reduce the insulation performance, greatly shorten the service life of the motor, and cause fire hazard and electric shock hazard.

Therefore, the purpose of motor overheat protection is mainly to adopt protective measures in the design, manufacture, installation and use of the motor. When the motor is operated under certain load and heat dissipation conditions, the temperature of the winding does not exceed the standard allowable value.

The dangers that may occur in motor-driven appliances during use are the risk of electric shock, fire and overheating. There are many reasons for the motor to overheat, such as overloading, improper selection, cooling failure, lack of monitoring, and necessary maintenance leading to premature insulation aging. The motor generates losses during operation. These losses reduce the efficiency of the motor on the one hand, and the loss of heat into the motor on the other hand, causing the temperature of the motor winding to rise. The service life of the winding insulation material is related to its working temperature. If the temperature is too high, the insulation material will accelerate aging, which will drastically reduce the insulation performance, greatly shorten the service life of the motor, and cause fire hazard and electric shock hazard.

Therefore, the purpose of motor overheat protection is mainly to adopt protective measures in the design, manufacture, installation and use of the motor. When the motor is operated under certain load and heat dissipation conditions, the temperature of the winding does not exceed the standard allowable value.

Related standards for motor overheat protection

There is a difference in the requirements for motor overheat protection in each country or each individual standard.

We use the Canadian Electrical Code (Canadian Electrical Code, Part I, Safety Standard for Electrical Installations). As an example, one of the Canadian National Standards of Canada (A National Standard of Canada)CAN/CSA-C22.2 NO.68 Motor-Operated Appliances(Household and Commercial). As an example, a brief interpretation of the standard requirements. The above two standards are standards set by the CSA (Canadian Standards Association) and adopted by the Canadian government as a national standard.

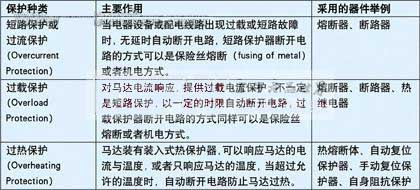

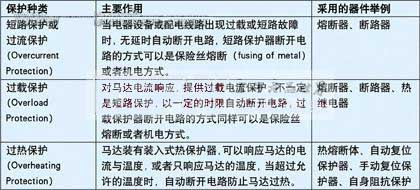

The classification and usage of the main motor protectors are shown in Table-1:

There is a difference in the requirements for motor overheat protection in each country or each individual standard.

We use the Canadian Electrical Code (Canadian Electrical Code, Part I, Safety Standard for Electrical Installations). As an example, one of the Canadian National Standards of Canada (A National Standard of Canada)CAN/CSA-C22.2 NO.68 Motor-Operated Appliances(Household and Commercial). As an example, a brief interpretation of the standard requirements. The above two standards are standards set by the CSA (Canadian Standards Association) and adopted by the Canadian government as a national standard.

The classification and usage of the main motor protectors are shown in Table-1:

Method for realizing motor overheat protection

Take Canadian National Standard / CSA Standard CAN/CSA-C22.2 NO.68 as an example. Learn how to implement motor overheat protection for motor-driven appliances to meet standard requirements. The standard lists the following pathways or possible scenarios:

(1) Use a motor-mounted thermal protector in accordance with CSA Standard C22.2 No. 77 Motor with Inherent Overheating Protection. These motor overheat protectors are listed in the above table. It should be noted that the protector should not only respond to the motor current, but also need to have the appropriate rated operating voltage, current value and temperature predetermined protection value, and the thermal protector needs to be applied to the motor. The tests required by the standard are Running Heating Temperature test, Locked-Rotor Temperature test and Locked-Rotor Endurance test. If the motor is in line with this standard, it can be marked "THERMALLY PROTECTED" (motor thermal protection). That is to say, when the motor meets the standard CSA68 of the whole machine and the motor standard CSA77. The motor meets the standard requirements under normal operating rating (Rating), overload heating (Locked-Rotor) applications, and the motor is overheat protected.

(2) If the motor is driven with the electrical overload protection device (Overload Protection device), overheat protection is not necessarily required. This situation must meet the requirements of CEC Part I. This overload protector is different from the overheat protector mentioned earlier. It only relies on the current of the response motor to achieve protection. It can be installed in the motor alone or in the motor for the choice of tripping current. The ratio of the tripping current of the protector to the rated current of the motor is generally not more than 1.15. If Fuses are chosen as the overload protector separately from the motor, the Fuse needs to use Time-delay fuse of the type ("D" Fuse).

(3) For some commercial electrical appliances, it is not necessary to install overload protectors in the electrical appliances when they need permanent connection to the distribution lines of buildings, but it is necessary to ensure that the distribution lines provide overload protection when the electrical appliances are installed and connected, and the electrical appliances need a warning label (CAUTION).

(4) For some specific electrical appliances, the standard exemption motor overheat protector. For example, the use of instantaneous contact switch (Momentary Contact Switch) to control motor appliances, hand-held appliances and household appliances with manned intermittent working system and built-in fuses. In addition, motor overheating protectors can also be exempted for household appliances with intermittent duty if they are evaluated by blocking test.

Take Canadian National Standard / CSA Standard CAN/CSA-C22.2 NO.68 as an example. Learn how to implement motor overheat protection for motor-driven appliances to meet standard requirements. The standard lists the following pathways or possible scenarios:

(1) Use a motor-mounted thermal protector in accordance with CSA Standard C22.2 No. 77 Motor with Inherent Overheating Protection. These motor overheat protectors are listed in the above table. It should be noted that the protector should not only respond to the motor current, but also need to have the appropriate rated operating voltage, current value and temperature predetermined protection value, and the thermal protector needs to be applied to the motor. The tests required by the standard are Running Heating Temperature test, Locked-Rotor Temperature test and Locked-Rotor Endurance test. If the motor is in line with this standard, it can be marked "THERMALLY PROTECTED" (motor thermal protection). That is to say, when the motor meets the standard CSA68 of the whole machine and the motor standard CSA77. The motor meets the standard requirements under normal operating rating (Rating), overload heating (Locked-Rotor) applications, and the motor is overheat protected.

(2) If the motor is driven with the electrical overload protection device (Overload Protection device), overheat protection is not necessarily required. This situation must meet the requirements of CEC Part I. This overload protector is different from the overheat protector mentioned earlier. It only relies on the current of the response motor to achieve protection. It can be installed in the motor alone or in the motor for the choice of tripping current. The ratio of the tripping current of the protector to the rated current of the motor is generally not more than 1.15. If Fuses are chosen as the overload protector separately from the motor, the Fuse needs to use Time-delay fuse of the type ("D" Fuse).

(3) For some commercial electrical appliances, it is not necessary to install overload protectors in the electrical appliances when they need permanent connection to the distribution lines of buildings, but it is necessary to ensure that the distribution lines provide overload protection when the electrical appliances are installed and connected, and the electrical appliances need a warning label (CAUTION).

(4) For some specific electrical appliances, the standard exemption motor overheat protector. For example, the use of instantaneous contact switch (Momentary Contact Switch) to control motor appliances, hand-held appliances and household appliances with manned intermittent working system and built-in fuses. In addition, motor overheating protectors can also be exempted for household appliances with intermittent duty if they are evaluated by blocking test.