NTC / PTC thermistor Material composition and Sintering process

Thermistor is a kind of temperature-sensitive components, Thermistors include Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC) thermistors. Positive temperature coefficient thermistor (PTC), The higher the temperature the greater the resistance value. Negative temperature coefficient thermistor (NTC), The higher the temperature the lower the resistance value, They belong to the same semiconductor device.

First, NTC thermistor NTC (Negative temperature coefficient) refers to the exponential relationship with the temperature rise resistance decreases, Thermistor phenomena and materials with negative temperature coefficient.

NTC thermistor development has gone through a long period. In 1834, the scientists first discovered the silver sulfide has a negative temperature coefficient characteristics. In 1930, the scientists found that cuprous oxide - copper oxide also has a negative temperature coefficient of performance, And the successful application of the temperature compensation circuit in the aviation instrument. As the transistor technology continues to develop, NTC thermistor research made significant progress.

NTC thermistor material composition:

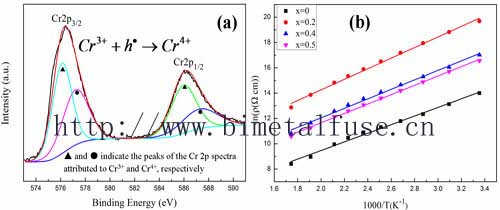

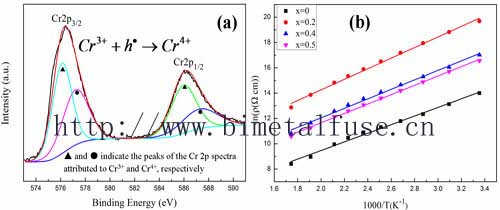

The material is a kind of semi-conductive ceramics made by using two or more kinds of metal oxides such as manganese, copper, silicon, cobalt, iron, nickel and zinc to fully mix, shape and sinter. Can be made with a negative temperature coefficient (NTC) of the thermistor. The resistivity and material constants vary with the material composition ratio, sintering atmosphere, sintering temperature and structure state. Non-oxide NTC thermistor materials such as silicon carbide, tin selenide, tantalum nitride and the like have also been developed.

The resistivity and material constants of the NTC thermistor vary with the material composition ratio, the sintering atmosphere, the sintering temperature and the structural state.

NTC thermistor material sintering process:

Yaxun electronic use of advanced sintering process:

New NTC thermistor sintered sag is made of high-temperature ceramic square or round structure;The bottom of the new NTC thermistor sintered sag is provided with a ventilation hole, The total area of the vent holes is 5% of the inner bottom area of the new NTC thermistor sintered sagger. This sagger to overcome the current NTC thermistor chip sintering, Due to temperature non-uniformity and atmosphere imbalance caused by the product resistance and B value of the dispersion. The use of this new NTC thermistor sintered sagger can greatly improve the yield of the product, So that the power NTC thermistor chip yield of 98% or more.

Co-Mn-O, Co-Mn-Ni-O, Mn-Ni-Cu-Fe-O and Co-Mn-Ni-Ru-O sintered.

NTC thermistor used in food storage, medicine and health, scientific farming, marine, deep wells, high altitude, glaciers, electrical, electronics, machinery, aviation and other aspects of temperature measurement.

NTC main manufacturers are: Yaxun, Shibaura, Murata, EPCOS, when the constant, and other enterprises

Second, ptc effect is a material with ptc (positive temperature coefficient) effect, Namely positive temperature coefficient effect, Only the resistance of this material will increase with increasing temperature. Such as most metal materials have ptc effect.

1. PTC thermistor material sintering process:

PTC (Positive Temperature Coeff1Cient) refers to a temperature at a sharp increase in resistance, with a positive temperature coefficient of the thermistor phenomenon or material, Can be used as a constant temperature sensor. The material is a sintered body containing BaTiO3 or SrTiO3 or PbTiO3 as a main component. In which a small amount of Nb, Ta, Bi, Sb, Y, La and other oxides for atomic control and semi-Often such semiconductor materials such as BaTiO3 semi-conductive (body) porcelain; At the same time, adding Mn, Fe, Cu, Cr and other additives which increase the positive temperature coefficient of resistance. Using the general process of ceramic molding, high temperature sintering and leaving titanium and platinum and its solid solution semiconducting, Thereby obtaining a PTC thermistor material having a positive characteristic. The temperature coefficient and Curie temperature with the composition and sintering conditions (especially the cooling temperature) vary.

2. PTC thermistor raw materials and formulations based on the selection:

Barium titanate - based semiconductive ceramics are the basic materials for preparing positive temperature coefficient thermistors. PTC in addition to raw materials, such as barium carbonate and titanium dioxide, Various additives are often used to improve the performance of the PTC. The donor ions in the position of Ti4 + in barium titanate are Nb5 +, W6 +, Ta5 +, etc. , At the position of Ba2 + there are La2 +, Ce4 +, Y3 + and other rare earth ions and Bi3 +, Sb3 + and so on. In general, the amount of donor addition introduced by chemical co-deposition to promote the semiconducting of the barium titanate-based porcelain is only 20 to 25% of the amount introduced by the oxide mixture method. In general, the amount of the donor added is limited to a very narrow range, That is, barium titanate-based ceramics semiconducting is very sensitive to the doping amount of donor.

Sn4 +, Sr2 + and Pb2 + are the main peaks of BaTiO3-based ceramics, Sn4 + and Sr2 + are positive temperature coefficient of the thermistor of the take-off temperature to low temperature, Is a low temperature with a positive temperature coefficient of thermal resistance of the commonly used peak shift to join, Pb2 + to take-off temperature shift to high temperature, Is a high temperature with a positive temperature coefficient thermistor commonly used to join.

Iron, manganese, chromium, copper, potassium, sodium, magnesium, etc. in the barium titanate semiconducting ceramics are acceptor impurities, Toxic to the role of semiconducting, Raw materials and porcelain in the content of such impurities must be limited to a certain extent.

3. PTC thermistor process selection ingredients are as follows:

【(Ba1-xSrx)Ti1.01O3+0.11%(mol)Nb2O5】 +0.04%(mol)MnO2+0.06%(mol)Sb2O3+0.5%(mol)SiO2+0.167%(mol)Al2O3+0.1%(mol)Li2CO3;

PTC Thermistors The above formula is a formulation that causes the resistivity jump temperature (i.e., the Curie point Tc) to move to a lower temperature. The formula due to the addition of silicon dioxide and aluminum oxide, and the formula TiO2 excess, the general use of industrial raw materials suitable for firing in the air can be prepared good performance of the semiconductor temperature coefficient of positive thermal resistance ceramic. So the above formulations are suitable for industrial production. In addition, Mg2 + has strong inhibitory effect on the semiconducting of TiO2 and barium carbonate. However, in some industrial production, Mg2 + is introduced into TiO2 in order to improve its anti-reductive property. In industrial production, barium titanate-based semiconductors The amount of Mg2 + in the ceramic should be strictly controlled, and its content is generally within 0.05% (mol).Yaxun electronic applications in the development of modern high-performance high-temperature PTC thermistor material is of great significance, Because it directly affects the application of PTC. Therefore, this process design to select the third group of recipes as the design study.

Main raw materials and their purity: purity 99.2% high-quality powder BaCO3, purity 99.6% TiO2 powder and purity 99.5% SrO powder

Other raw materials (assuming 100% purity): Nb2O5, MnO2, Sb2O3, SiO2, Al2O3, Li2CO3, pure water and adhesives.

At present the main PTC thermistor manufacturers are: Murata, Yaxun, EPCOS, Ampere, Taiwan Hing-Qin, Shibaura, and other enterprises

First, NTC thermistor NTC (Negative temperature coefficient) refers to the exponential relationship with the temperature rise resistance decreases, Thermistor phenomena and materials with negative temperature coefficient.

NTC thermistor development has gone through a long period. In 1834, the scientists first discovered the silver sulfide has a negative temperature coefficient characteristics. In 1930, the scientists found that cuprous oxide - copper oxide also has a negative temperature coefficient of performance, And the successful application of the temperature compensation circuit in the aviation instrument. As the transistor technology continues to develop, NTC thermistor research made significant progress.

NTC thermistor material composition:

The material is a kind of semi-conductive ceramics made by using two or more kinds of metal oxides such as manganese, copper, silicon, cobalt, iron, nickel and zinc to fully mix, shape and sinter. Can be made with a negative temperature coefficient (NTC) of the thermistor. The resistivity and material constants vary with the material composition ratio, sintering atmosphere, sintering temperature and structure state. Non-oxide NTC thermistor materials such as silicon carbide, tin selenide, tantalum nitride and the like have also been developed.

The resistivity and material constants of the NTC thermistor vary with the material composition ratio, the sintering atmosphere, the sintering temperature and the structural state.

NTC thermistor material sintering process:

Yaxun electronic use of advanced sintering process:

New NTC thermistor sintered sag is made of high-temperature ceramic square or round structure;The bottom of the new NTC thermistor sintered sag is provided with a ventilation hole, The total area of the vent holes is 5% of the inner bottom area of the new NTC thermistor sintered sagger. This sagger to overcome the current NTC thermistor chip sintering, Due to temperature non-uniformity and atmosphere imbalance caused by the product resistance and B value of the dispersion. The use of this new NTC thermistor sintered sagger can greatly improve the yield of the product, So that the power NTC thermistor chip yield of 98% or more.

Co-Mn-O, Co-Mn-Ni-O, Mn-Ni-Cu-Fe-O and Co-Mn-Ni-Ru-O sintered.

NTC thermistor used in food storage, medicine and health, scientific farming, marine, deep wells, high altitude, glaciers, electrical, electronics, machinery, aviation and other aspects of temperature measurement.

NTC main manufacturers are: Yaxun, Shibaura, Murata, EPCOS, when the constant, and other enterprises

Second, ptc effect is a material with ptc (positive temperature coefficient) effect, Namely positive temperature coefficient effect, Only the resistance of this material will increase with increasing temperature. Such as most metal materials have ptc effect.

1. PTC thermistor material sintering process:

PTC (Positive Temperature Coeff1Cient) refers to a temperature at a sharp increase in resistance, with a positive temperature coefficient of the thermistor phenomenon or material, Can be used as a constant temperature sensor. The material is a sintered body containing BaTiO3 or SrTiO3 or PbTiO3 as a main component. In which a small amount of Nb, Ta, Bi, Sb, Y, La and other oxides for atomic control and semi-Often such semiconductor materials such as BaTiO3 semi-conductive (body) porcelain; At the same time, adding Mn, Fe, Cu, Cr and other additives which increase the positive temperature coefficient of resistance. Using the general process of ceramic molding, high temperature sintering and leaving titanium and platinum and its solid solution semiconducting, Thereby obtaining a PTC thermistor material having a positive characteristic. The temperature coefficient and Curie temperature with the composition and sintering conditions (especially the cooling temperature) vary.

2. PTC thermistor raw materials and formulations based on the selection:

Barium titanate - based semiconductive ceramics are the basic materials for preparing positive temperature coefficient thermistors. PTC in addition to raw materials, such as barium carbonate and titanium dioxide, Various additives are often used to improve the performance of the PTC. The donor ions in the position of Ti4 + in barium titanate are Nb5 +, W6 +, Ta5 +, etc. , At the position of Ba2 + there are La2 +, Ce4 +, Y3 + and other rare earth ions and Bi3 +, Sb3 + and so on. In general, the amount of donor addition introduced by chemical co-deposition to promote the semiconducting of the barium titanate-based porcelain is only 20 to 25% of the amount introduced by the oxide mixture method. In general, the amount of the donor added is limited to a very narrow range, That is, barium titanate-based ceramics semiconducting is very sensitive to the doping amount of donor.

Sn4 +, Sr2 + and Pb2 + are the main peaks of BaTiO3-based ceramics, Sn4 + and Sr2 + are positive temperature coefficient of the thermistor of the take-off temperature to low temperature, Is a low temperature with a positive temperature coefficient of thermal resistance of the commonly used peak shift to join, Pb2 + to take-off temperature shift to high temperature, Is a high temperature with a positive temperature coefficient thermistor commonly used to join.

Iron, manganese, chromium, copper, potassium, sodium, magnesium, etc. in the barium titanate semiconducting ceramics are acceptor impurities, Toxic to the role of semiconducting, Raw materials and porcelain in the content of such impurities must be limited to a certain extent.

3. PTC thermistor process selection ingredients are as follows:

【(Ba1-xSrx)Ti1.01O3+0.11%(mol)Nb2O5】 +0.04%(mol)MnO2+0.06%(mol)Sb2O3+0.5%(mol)SiO2+0.167%(mol)Al2O3+0.1%(mol)Li2CO3;

PTC Thermistors The above formula is a formulation that causes the resistivity jump temperature (i.e., the Curie point Tc) to move to a lower temperature. The formula due to the addition of silicon dioxide and aluminum oxide, and the formula TiO2 excess, the general use of industrial raw materials suitable for firing in the air can be prepared good performance of the semiconductor temperature coefficient of positive thermal resistance ceramic. So the above formulations are suitable for industrial production. In addition, Mg2 + has strong inhibitory effect on the semiconducting of TiO2 and barium carbonate. However, in some industrial production, Mg2 + is introduced into TiO2 in order to improve its anti-reductive property. In industrial production, barium titanate-based semiconductors The amount of Mg2 + in the ceramic should be strictly controlled, and its content is generally within 0.05% (mol).Yaxun electronic applications in the development of modern high-performance high-temperature PTC thermistor material is of great significance, Because it directly affects the application of PTC. Therefore, this process design to select the third group of recipes as the design study.

Main raw materials and their purity: purity 99.2% high-quality powder BaCO3, purity 99.6% TiO2 powder and purity 99.5% SrO powder

Other raw materials (assuming 100% purity): Nb2O5, MnO2, Sb2O3, SiO2, Al2O3, Li2CO3, pure water and adhesives.

At present the main PTC thermistor manufacturers are: Murata, Yaxun, EPCOS, Ampere, Taiwan Hing-Qin, Shibaura, and other enterprises