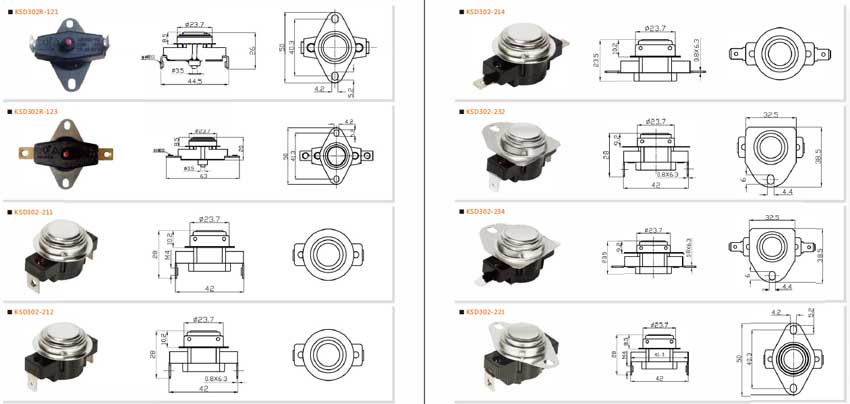

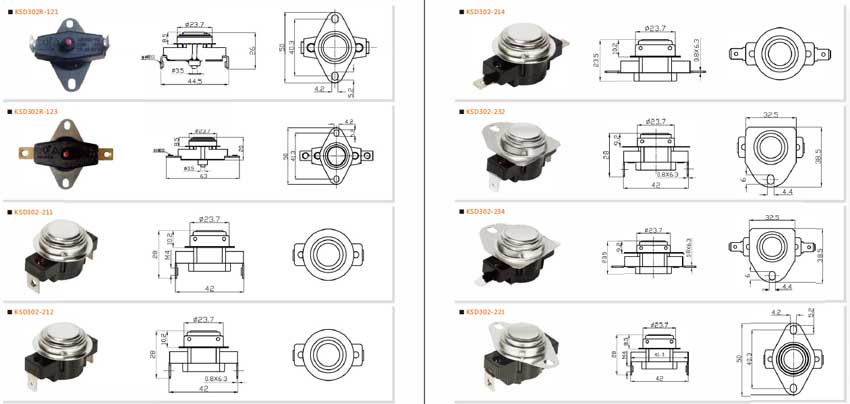

Choose SPST Thermal Switch

SPST thermal switch functions (high power and low current) and thermostatic control applications:

Thermostats are divided into: SPST thermal switches, bimetallic thermostats, waterproof, and dry-heat-proof thermostat switches.

Most electrical appliances and kettles with thermal insulation function have two heating pipes, and one of the thermal insulation heating pipes is independently controlled by the SPST thermal switch. It allows users to control whether to keep warm or not. The thermal insulation power is generally below 50W, and the power consumption usually does not exceed 0.1 kilowatt hour per hour. Because today's electric kettles can boil water very quickly, and it only takes four or five minutes to boil a pot of water. When the heating tube boils the water, the power will be automatically cut off. At this time, the insulation pipe begins to work. The heating temperature of the insulation tube is between 70 and 80 degrees, which can keep the water at a constant temperature.

Key components: The key component of the electric kettle is the SPST thermostat. The quality and service life of the SPST thermostat determine the quality and service life of the kettle. It is recommended that consumers choose a thermostat electric kettle that is waterproof and prevents dry boiling.

Key components: The key component of the electric kettle is the SPST thermostat. The quality and service life of the SPST thermostat determine the quality and service life of the kettle. It is recommended that consumers choose a thermostat electric kettle that is waterproof and prevents dry boiling.

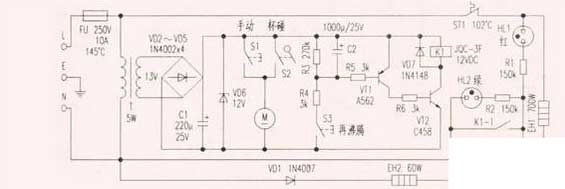

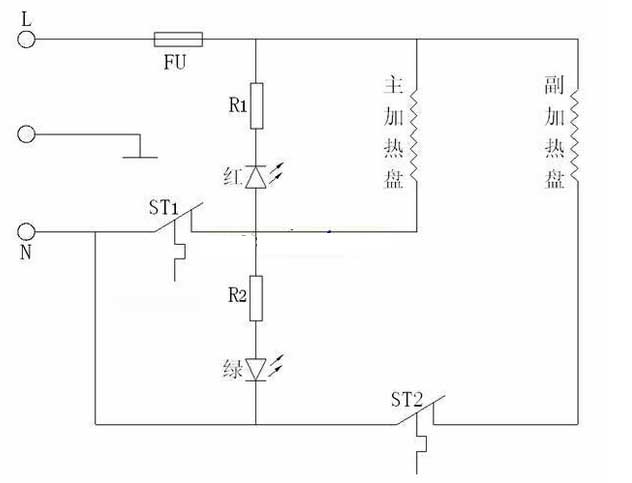

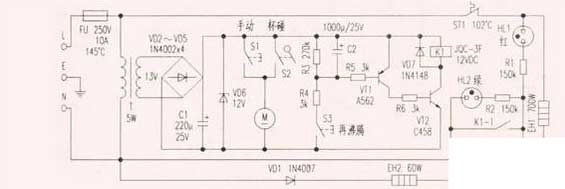

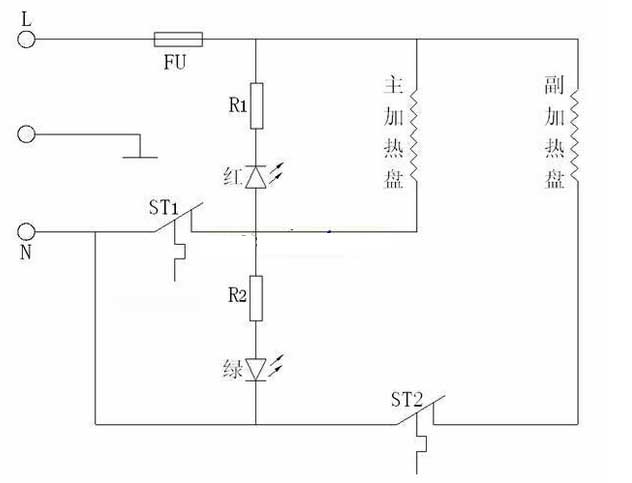

It consists of anti-dry heating thermostat st1, main heater eh1, heating thermostat st2, rectifier diode vd1, insulation heater eh2, heating indicator light hl1, insulation indicator light hl2 and other components. Turn on the power, and the 220v mains power is added to eh1 through the over-temperature fuse fu to heat the water in the bottle. At the same time, hl1 displays red light, indicating that the thermos bottle has entered the heating state. Since hl2 and r2, vd1 and eh2 are connected in series and are short-circuited by st2, hl2 does not light up and eh2 does not heat. When the water in the bottle is boiled, the st2 contact is automatically disconnected, cutting off the power supply of the heating circuit, eh1 does not heat, and hl1 goes out. At this time, vd1 half-wave rectification supplies power to eh2 and eh1. Since eh2 and eh1 are connected in series, and the resistance of eh1 is very small, almost all the half-wave rectified voltage is applied to eh2. eh2 heats at half power (i.e. 30w) to keep the boiling water warm for a long time. At the same time, hl2 has current flowing through it and displays green Light indicates that the thermos bottle has entered the heat preservation state.

It consists of anti-dry heating thermostat st1, main heater eh1, heating thermostat st2, rectifier diode vd1, insulation heater eh2, heating indicator light hl1, insulation indicator light hl2 and other components. Turn on the power, and the 220v mains power is added to eh1 through the over-temperature fuse fu to heat the water in the bottle. At the same time, hl1 displays red light, indicating that the thermos bottle has entered the heating state. Since hl2 and r2, vd1 and eh2 are connected in series and are short-circuited by st2, hl2 does not light up and eh2 does not heat. When the water in the bottle is boiled, the st2 contact is automatically disconnected, cutting off the power supply of the heating circuit, eh1 does not heat, and hl1 goes out. At this time, vd1 half-wave rectification supplies power to eh2 and eh1. Since eh2 and eh1 are connected in series, and the resistance of eh1 is very small, almost all the half-wave rectified voltage is applied to eh2. eh2 heats at half power (i.e. 30w) to keep the boiling water warm for a long time. At the same time, hl2 has current flowing through it and displays green Light indicates that the thermos bottle has entered the heat preservation state.

Using PTC heating elements instead of heating tubes can effectively prevent the risk of fire caused by dry burning. The dry heating temperature of the PTC heating element can be set at any temperature between 150°C and 250°C. When the temperature reaches the set temperature, the resistance of the PTC element increases rapidly and the heating power drops sharply, keeping the temperature at the set temperature without continuing to rise. The automatic temperature control performance of PTC heating elements is absolutely reliable. It relies on the resistance change within the PTC body to control the temperature, rather than relying on any contact control. Therefore, many high-end electric kettles now use PTC anti-heat elements.

However, because many electric kettle designers are not accustomed to using PTC heating elements, and the price of PTC is relatively high and the volume is relatively large, its application is limited.

However, because many electric kettle designers are not accustomed to using PTC heating elements, and the price of PTC is relatively high and the volume is relatively large, its application is limited.

PTC heating elements have great advantages when used for heat preservation of electric kettles. The heat preservation power of the electric kettle is relatively small, and using PTC heating elements will not increase the cost much. The PTC heating element has an anti-dry burning function, and its dry burning power is about one-tenth of the water boiling power. In the event of failure of the temperature control element, the PTC's own temperature remains at a lower temperature and no danger will occur.

Thermostats are divided into: SPST thermal switches, bimetallic thermostats, waterproof, and dry-heat-proof thermostat switches.

Most electrical appliances and kettles with thermal insulation function have two heating pipes, and one of the thermal insulation heating pipes is independently controlled by the SPST thermal switch. It allows users to control whether to keep warm or not. The thermal insulation power is generally below 50W, and the power consumption usually does not exceed 0.1 kilowatt hour per hour. Because today's electric kettles can boil water very quickly, and it only takes four or five minutes to boil a pot of water. When the heating tube boils the water, the power will be automatically cut off. At this time, the insulation pipe begins to work. The heating temperature of the insulation tube is between 70 and 80 degrees, which can keep the water at a constant temperature.

Using PTC heating elements instead of heating tubes can effectively prevent the risk of fire caused by dry burning. The dry heating temperature of the PTC heating element can be set at any temperature between 150°C and 250°C. When the temperature reaches the set temperature, the resistance of the PTC element increases rapidly and the heating power drops sharply, keeping the temperature at the set temperature without continuing to rise. The automatic temperature control performance of PTC heating elements is absolutely reliable. It relies on the resistance change within the PTC body to control the temperature, rather than relying on any contact control. Therefore, many high-end electric kettles now use PTC anti-heat elements.

PTC heating elements have great advantages when used for heat preservation of electric kettles. The heat preservation power of the electric kettle is relatively small, and using PTC heating elements will not increase the cost much. The PTC heating element has an anti-dry burning function, and its dry burning power is about one-tenth of the water boiling power. In the event of failure of the temperature control element, the PTC's own temperature remains at a lower temperature and no danger will occur.