Miniature overheat protector

The new type of micro-bimetallic overheat protector is a small-sized overheating cut-off switch in the field of electronics and electrical appliances. It is a temperature switch with no noise, high sensitivity and easy installation. It is especially suitable for heating fields where miniature tubular motors, batteries, circuit boards and small spaces are required.

Technological innovation:

In the prior art, the overheat protector mostly adopts a bimetallic overcurrent design. Because of the small size, the current effect of the bimetal is relatively large, so the protection temperature will be unreliable. Although some temperature switch manufacturers have adopted bimetal no-current design, due to the unreasonable design, the thermal protector is noisy and is not conducive to high-efficiency production.

New invention content

The purpose of the utility model is to provide a miniature bimetallic sheet type overheat protector for the above-mentioned shortcomings. The product structure design of this miniature bimetal thermal protector is reasonable, the current effect is small, the temperature control is accurate, it is suitable for automatic production, and it is noiseless, and the product quality is stable and reliable.

The miniature bimetallic sheet overheat protector is realized by adopting the following technical schemes:

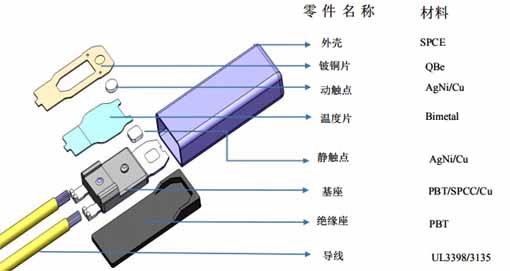

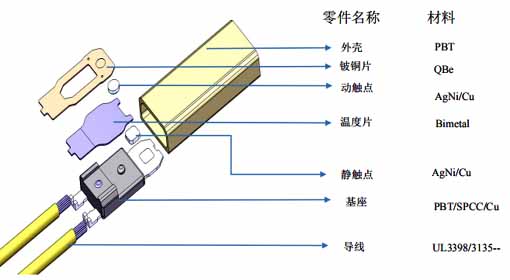

The overheat protector of the miniature bimetal includes a shell, a lower terminal, a moving contact, a static contact, a bimetal element, an elastic conductive sheet, an upper terminal, a fixing seat, a sealant and a wire; One end of the upper terminal is provided with a wire welding positioning claw, the other end is provided with an elastic conductive sheet connection boss, and one end of the lower terminal is provided with a wire welding positioning claw; The middle end is provided with a fixing seat connection ring, and the other end is provided with a static contact; The wire welding positioning claw provided at one end of the upper terminal and the wire welding positioning claw provided at one end of the lower terminal are respectively welded with wires; Place the upper terminal and the lower terminal in a plastic mold at the same time for injection processing to form a fixed seat assembly; Place the bimetal element in the groove of the fixing seat, and the hole with the hole end of the bimetal element is sleeved on the connecting boss of the elastic conductive sheet of the upper terminal; Then the elastic conductive sheet provided with the movable contact is placed above the bimetal element, and the other end of the elastic conductive sheet is connected with the elastic conductive sheet connecting boss provided on the upper terminal to form a thermal protector assembly; Put the thermal protector assembly on the shell and fix it with sealant.

One end of the fixed seat is provided with an overturning boss of a bimetal element.

The bimetal element is provided with a bimetal element overturning stress ring and a C-shaped groove released from the bimetal element slow motion zone.

There is at least one fixing seat connecting ring provided at the middle end of the lower terminal.

The bimetal element is provided with a groove surface (high expansion surface) and a convex surface (low expansion surface). The bimetal element can make a normally closed temperature switch with the groove surface (high expansion surface) downward. The convex surface (low expansion surface) of the bimetal element can also be used to make a normally open temperature switch.

The working principle of the miniature bimetallic thermal protector:

When the temperature of the electrical component to be protected is abnormally high, the bimetal element of the overheat protector feels the set temperature. Quickly reverse and push open the spring plate to disconnect the moving contact from the static contact, and the main circuit of the protected electrical component is quickly disconnected to avoid damage.

When the temperature drops to the reset temperature of the bimetallic element, the bimetallic strip resumes inversion. The movable contact and the static contact of the miniature thermal protector are closed, and the main circuit of the electrical component to be protected is reconnected to restore the normal working state.

The miniature overheat protector has reasonable design and compact structure. It is a pure temperature type, precise temperature control, no noise, small size and suitable for automatic production of temperature switches. The product structure of the miniature thermal protector is reasonable, the current effect is small, and there is no noise, and the product quality is stable and reliable.